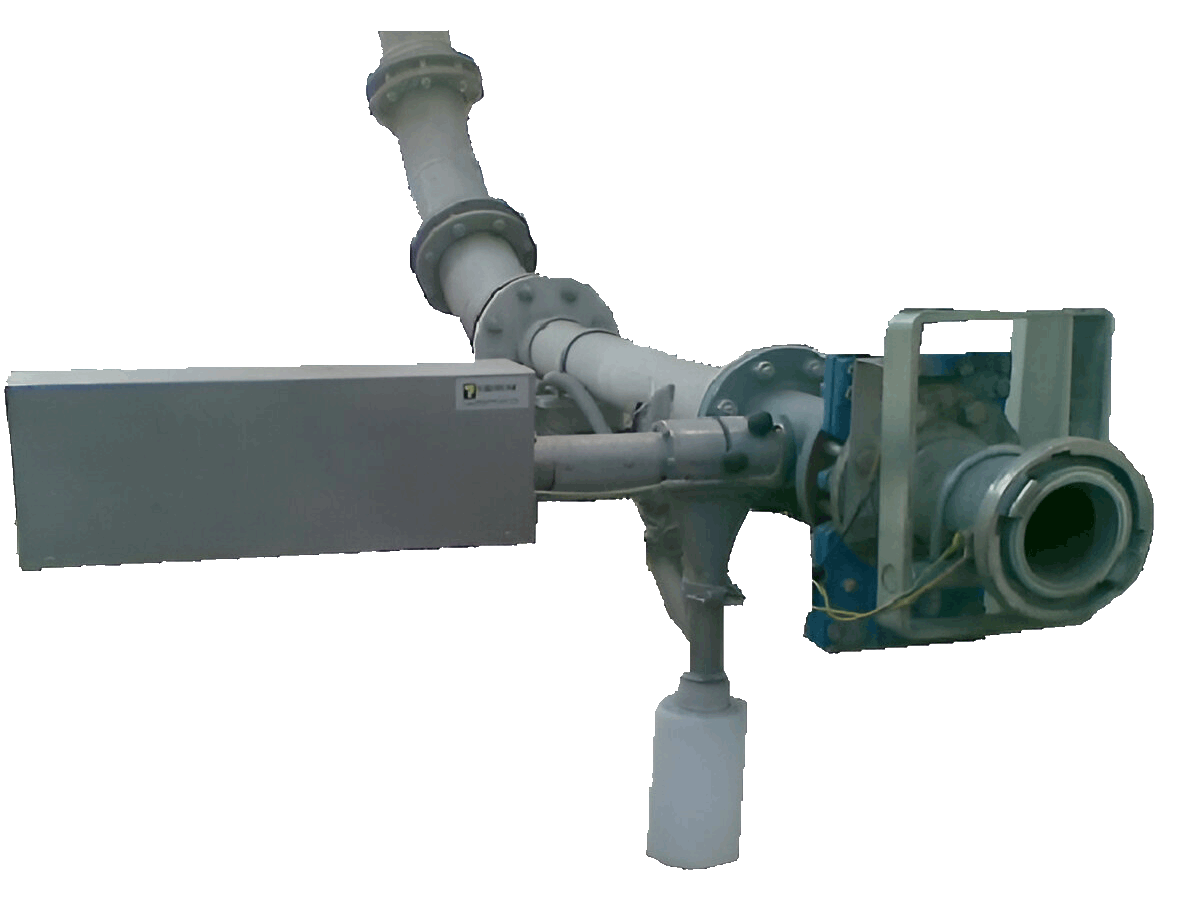

This device takes a “specimen” of the product being transported at a point in the pipe.

The frequency of sampling ensures greater representativeness.

At rest, the passage of the product is completely free.

Sampling is carried out by the penetration of a piston open at the end to capture the product over a given section. The sample flows into the duct until it fills (maximum sample volume). Capacity adapted to requirements.

Once the piston is retracted, gas is injected into the implant boss to clean the sampler and propel the sample if necessary.

Each sampler is designed and sized to meet the customer's needs.

We adapt the sampler:

All components are made from materials suited to the product and operating conditions (generally stainless steel) and are particularly robust.

When waiting to be tapped, the piston is retracted, leaving the DN 250 circuit completely free.

Direct debit :

A stand-alone control panel is used to control the sampling cycle and program the settings required for the operation.Material: 304 L stainless steel