Mechanical action on the pump handle creates a vacuum inside the vacuum chamber, the bottle and the sampling tube.

Suction causes the liquid to rise up inside the sampling tube and directly fill the sample pot or bottle.

The sampling tube, which is in contact with the product, can be immersed in various containers (tank, barrel or sump).

It can be removed without risk of leakage using the self-sealing connector.

It can be dismantled so that the part in contact with the product can be sterilised.

from 40 to 1,000 ml in jars, bottles or flasks according to standard or adapted to your needs.

Length of probe on request: from 200 mm to 2.5 metres (in several elements if necessary).

Fit the sample pot onto the connecting piece, tightening it moderately if it is made of PTFE (its longevity depends on this), otherwise tighten it sufficiently to ensure a seal during sampling.

Insert the probe into the product and connect it to the self-sealing connector on the sampling head.

Pump out the required volume (be careful to limit the volume to the pot).

Disconnect the probe (the self-sealing connector prevents dripping).

The sample pot is ready to be dismantled and capped.

Disconnect the sampling tube. Replace with the rinse nozzle and inject the cleaning product.

Elements in contact with the product :

Dismantling the connecting piece :

Insert the rinse nozzle into the quick connector (to ensure better sterilisation by circulation).

Maximum temperature, must not exceed 180°C, as the seal is not part of the components to be sterilised.

Reactor mounting.

Can be adapted for other jars and bottles.

We can make probes to your specific requirements, including connecting parts, in the materials and dimensions you require.

This probe can be used to sample liquids and charged liquids. All its components can be food-grade on request.

Using the control box and a mechanical rail, the tube is lowered into the product to be sampled, and suction is triggered.

Suction causes the liquid to rise up inside the sampling tube and directly fill the sample pot or bottle.

The sampling tube, which is in contact with the product, can be immersed in various containers (tank, barrel or sump).

The product contact tube can be replaced.

Samples: from 40 to 10,000 ml in jars, bottles or flasks according to standard or adapted to your needs.

Probe length on request: from 200 mm to 2 m.

Capable of pumping water and oil up to a viscosity of 15,000 cP max.

Mount the sample pot on the stand. Connect the sampling tube to the pump.

Insert the probe tube into the product and pump out the required volume.

Repeat sampling until the desired volume is reached.

If necessary, disconnect the tube from the probe (to avoid contamination).

The sample pot is ready to be removed and capped.

Suction tube: PMMA

Pump : Silicone tube

Disconnect the tube from the pump and the sampling tube.

Replace or wash the components.

Can be adapted to other jars and bottles.

Nota: We can make probes to your specific requirements, including connecting parts, in the materials and dimensions required.

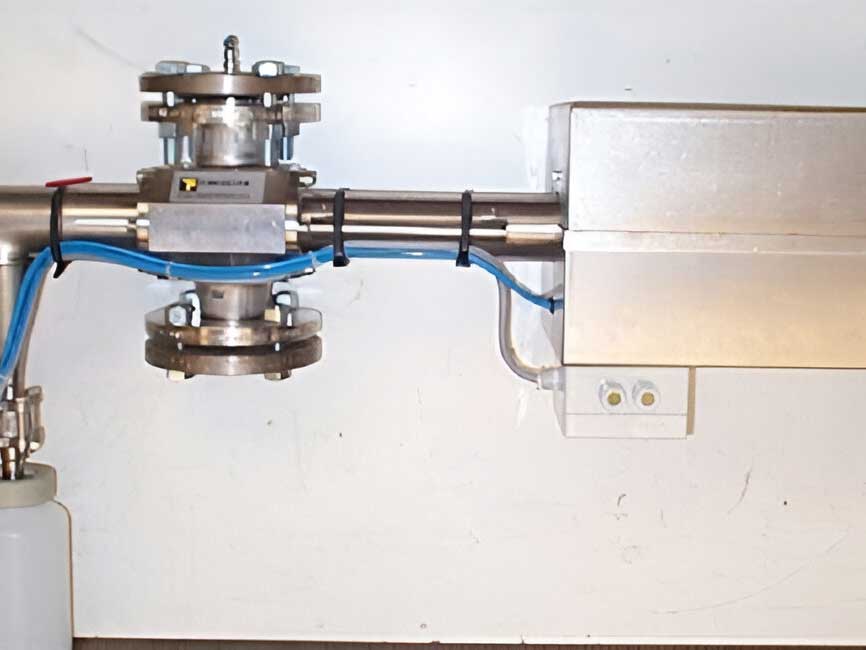

On transfer piping for liquids and possibly pneumatic transport.

A tangential (cavity) piston is driven in translation by a cylinder.

Each movement evacuates a sample corresponding to the volume of the impression.

During operation, the pipe cross-section is only partially obstructed, which prevents "water hammer".

If necessary, a safety valve provides an SAS function.

An electro-pneumatic or pneumatic control box enables the sampling cycle to be established manually or automatically (programmed) and to provide the safety features required for operating conditions.

This sampler is designed to be mounted on a pipe, between two flanges, and is adjustable.

All parts in contact with the product are stainless steel (stainless steel, PTFE, Viton) and depend on the operating conditions and the nature of the product.

Maximum operating pressure 16 bar (depending on model).